Aries IPSA’s premises cover an area of more than 7,000 m2 devoted to manufacture of pieces by thermoplastic injection. In our effort to provide the widest range of manufacturing solutions for our clients we also perform composition of components, ultrasonic welding, paintwork, laser cutting, tampography, thermographic printing, plate cutting, silver contact printing and plate bending.

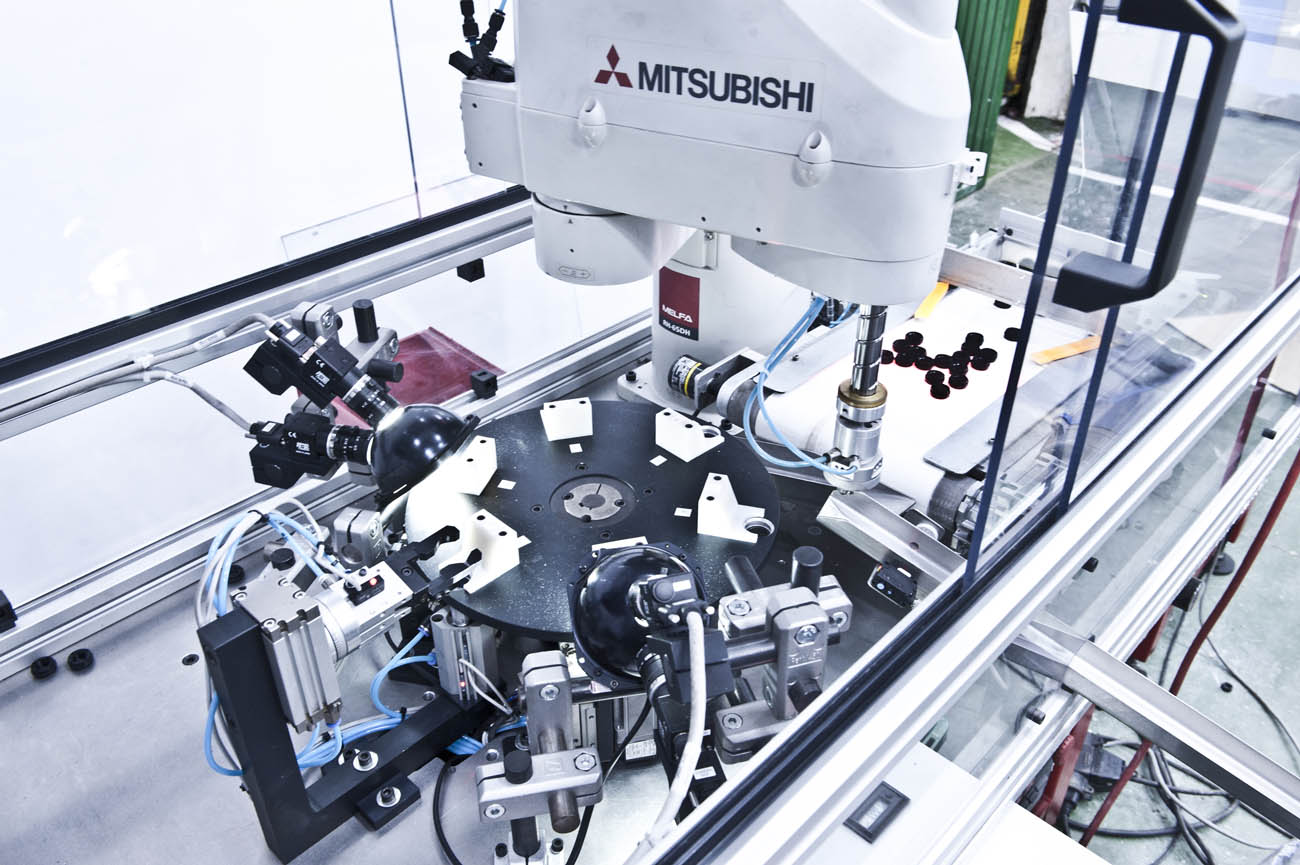

If we can conceive it, we can do it. That’s why we have a machinery pool with more than 37 machines with strokes of between 35 and 1,300 tonne and vertical or horizontal injection.

We also have a mould-making workshop that enables us to provide mould repair and small mould manufacturing services.

With the aim of improving the end result of our products we have added IML technology (in-mould labelling) to our production process. This is an advanced decoration system in the plastic injection moulding process. It enables us to incorporate decoration into plastic products and thus enhance their visual quality.